Blackjack has got the best odds of successful, that have property side of less than step 1% at most gambling enterprises. Since the player are definitely doing work in decision making on the video game, the odds out of winning during the black-jack is increased by using earliest means. Might blackjack laws and regulations are to score a hand nearer to 21 versus agent rather than splitting.

Authorized Gambling enterprises

Remember, a well-chose site enhances your own playing sense while offering reassurance. Successful ‘s the ultimate goal of one’s most of bettors, no matter https://vogueplay.com/uk/trada-casino-review/ what games it’re playing. So, it’s no wonder a lot of myths and you may tales have been designed to it. As an alternative, i advise you to place your have confidence in your understanding from blackjack as well as regulations, opportunity, and strategies. But not, you must know when you should walk off regarding the blackjack table. Stick to their bankroll government approach, regard your using constraints, and you may wear’t rating fooled by the profitable and you can losing lines.

- Yet not, it’s maybe not nearly because the fun otherwise useful because the regular gameplay.

- In the totally free setting, it’s allowed to gamble slot machines instead registration after looking her or him.

- Continue scrolling if you need present-day factual statements about an informed house-based gambling enterprises in the usa offering blackjack and the states in which to play the video game is court.

- For those who’re also keen on traditional gambling enterprises, learning first blackjack dining table gestures is vital.

- Northern Gambling establishment, such as, process withdrawals quickly, improving the consumer experience and you can ensuring that players have access to its winnings without delay.

- Live baccarat’s strategic depth and interesting game play allow it to be popular one of of numerous professionals.

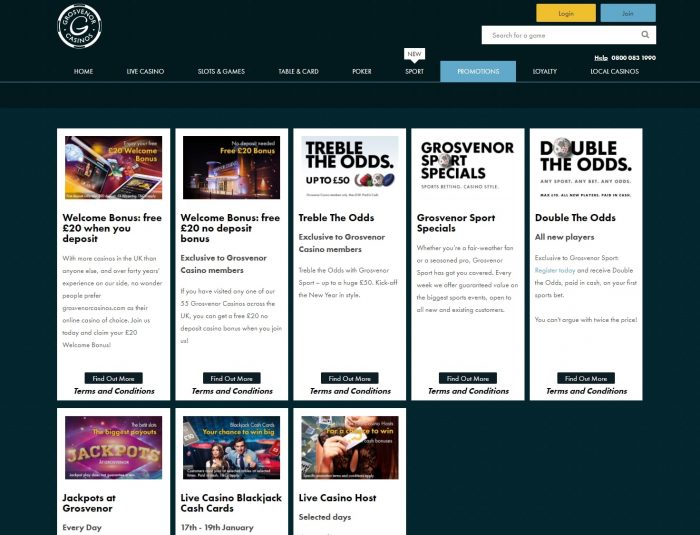

Best Also provides Which Day:

If your dealer has blackjack with an opening credit that is an excellent ten card (10, jack, queen, otherwise queen), then specialist instantly victories. The fresh Canadian province of Quebec is, unfortunately, and off the checklist. Choice at the individual chance and never spend money you can’t afford to get rid of. The new guide on this site is actually informative and you will intended to present your having upwards-to-go out details about the online betting landscape.

What is the family advantage in the black-jack?

It’s unlikely the user are certain to get an expert 2nd, as well as the user must always remain. Land-centered gambling enterprises are legal, typically, in the most common All of us states. You only won’t discover belongings-founded casino sites inside the Utah, Sc, Georgia, and you can The state. The modern models out of blackjack that exist tend to be vintage, vintage unmarried-platform, double-patio, European, prime couple, and you may Zappit.

These types of live specialist casino games also are well liked due to their legitimacy, ensured by the good playing permits and you may sturdy defense standards such encryption technical. Begin to try out the real deal currency only if you’re completely alert of everything about your the fresh game. CSMs shuffle cards after every bullet, which means that much more give might possibly be dealt hourly, along with your bankroll are more opened. Mechanical shufflers and you will real time people shuffle notes simply just after 50% or 75% of these were played, so they really leave you a better danger of successful. They can change the choice provide, winning opportunity, and you can house edge rather. Therefore, it’s vital that you look at how favorable he’s to possess participants before you choose whether to sit at a certain table.

Household boundary and you will chance inside online blackjack

Withdrawing finance often requires several verification steps, such confirming your term and you will validating the new fee membership within the question. In some occasions, participants could be limited by cashing off to the original deposit account. For many who highlight exchange security, each other gambling on line internet sites which have Gamble+ and you can American Display gambling on line internet sites in america render trustworthy alternatives. Remember that almost any equipment you might want – a pc or a compact one – you’ll get access to the same amount of black-jack games.

Can you play blackjack on the web for the money?

People is lay bets because of a combination of live video footage and you will pop-up keys, carrying out a seamless and immersive experience in live casino games. Fans is the agent that people highly recommend in order to players who gamble Pennsylvania casinos on the internet. Within the 2024, the internet local casino went reside in the newest Keystone County, offering online blackjack to everyone life indeed there. Players can also be compete keenly against a real dealer otherwise a computer — regardless, the outcome try arbitrary. While you are in a condition where casinos on the internet is courtroom, the pros wrote this article to display the finest blackjack casinos readily available. Lower than try our done on line black-jack book, such as the best variations, bonuses, and you will wagers.