In the modern era of space exploration and satellite technology, precision, reliability, and durability are more than just buzzwords—they are mission-critical requirements. Every satellite, whether it’s for communication, navigation, weather monitoring, or defense, relies on sophisticated electronics to function flawlessly in space. At the heart of these electronics are printed circuit boards (PCBs), and working with an experienced aerospace PCB manufacturer is essential to ensure the success of satellite missions.

At Insight PCB, we specialize in manufacturing high-reliability aerospace PCBs designed to thrive in extreme conditions, helping satellites operate seamlessly for years in orbit.

The Importance of PCBs in Satellite Systems

Satellites are exposed to conditions that no terrestrial electronics face:

- Extreme temperatures: Satellites endure both intense heat from the sun and freezing cold in the shadow of Earth.

- Radiation exposure: High-energy particles can damage sensitive electronics.

- Vibration and shock: Launches generate tremendous forces that can compromise poorly designed boards.

- Long-term reliability: Once in orbit, repairs are impossible, so electronics must function flawlessly for years.

PCBs act as the backbone of every satellite system, connecting components, managing power, and ensuring data flows accurately. Without robust aerospace PCBs, even the most advanced satellite designs would fail before achieving their mission goals

How Aerospace PCB Manufacturers Support Satellites

Experienced aerospace PCB manufacturers, like Insight PCB, play a crucial role in every stage of satellite development:

1. Design for Extreme Conditions

Aerospace PCB manufacturers design boards using specialized materials such as polyimide, ceramic substrates, or metal core laminates. These materials resist thermal stress, maintain signal integrity, and withstand radiation in space. Controlled impedance and high-density interconnect (HDI) designs ensure reliable communication between satellite subsystems.

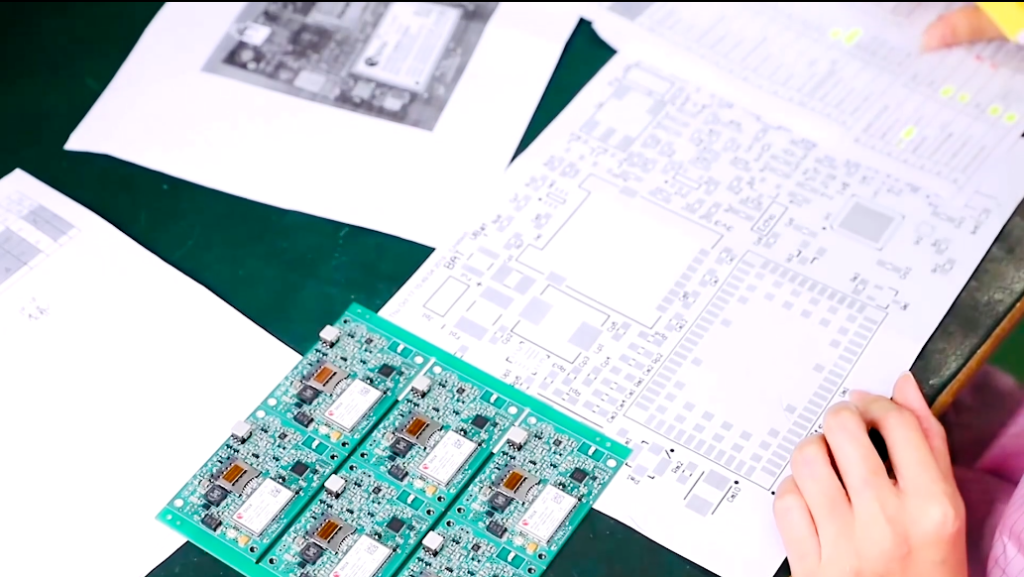

2. Advanced Fabrication Techniques

Manufacturing satellite PCBs demands precision. Techniques include:

- Microvia and via-in-pad designs for compact layouts.

- Heavy copper plating for power distribution.

- Multilayer PCBs to handle complex signal routing.

- Surface finishes compatible with long-term space operation.

These methods guarantee that the boards are robust enough to survive launch vibrations and operate consistently in orbit.

3. Testing and Quality Assurance

Satellite PCBs undergo rigorous testing before deployment. Aerospace PCB manufacturers perform:

- Thermal cycling to simulate extreme temperature changes.

- Vibration and shock tests to replicate launch conditions.

- Electrical testing to ensure signal integrity and reliability.

- X-ray inspection for micro-defect detection.

At Insight PCB, we maintain a 99.8% quality assurance pass rate, ensuring that every board meets the highest standards before delivery.

4. Compliance with Aerospace Standards

Satellites must meet strict global standards. A trusted aerospace PCB manufacturer complies with certifications such as:

- AS9100D for aerospace quality management

- ISO 9001 for consistent production quality

- IPC standards for board fabrication and assembly

These certifications demonstrate that the manufacturer can consistently deliver boards that perform under mission-critical conditions.

Real-World Applications of Satellite PCBs

PCBs designed for satellites serve a variety of functions:

- Communication satellites: PCBs handle signal processing for TV, internet, and mobile communications.

- Navigation satellites: Precision electronics ensure GPS accuracy.

- Earth observation satellites: PCBs power imaging systems, sensors, and data transmission.

- Scientific and defense satellites: Specialized boards maintain critical instrumentation in extreme environments.

In all these applications, the performance of aerospace PCBs can determine mission success or failure.

Why Partnering with Insight PCB Matters

At Insight PCB, we combine decades of expertise with cutting-edge technology to deliver PCBs that support satellite systems worldwide. Here’s why aerospace engineers choose us:

- Decades of Experience: Over 35 years in high-reliability PCB manufacturing.

- Global Reach: Serving clients across six continents with precision and consistency.

- Advanced Capabilities: Rigid, flex, rigid-flex, HDI, and metal core boards tailored for aerospace applications.

- Certified Excellence: AS9100D, ISO9001, ISO14001, RoHS, and UL certifications ensure trusted performance.

- Customer-Focused Solutions: From prototype to full-scale production, we provide cost-effective, reliable PCBs built to thrive in the harshest conditions.

The Future of Aerospace PCB Manufacturing for Satellites

With the rapid expansion of satellite constellations, autonomous space vehicles, and advanced scientific missions, aerospace PCB manufacturers face exciting challenges and opportunities. Trends include:

- Miniaturization for small satellites (CubeSats and nanosatellites)

- High-frequency PCBs for faster communication and data transfer

- Radiation-hardened PCBs for deep-space missions

- Eco-friendly manufacturing practices to reduce environmental impact

Through innovation and precision, manufacturers like Insight PCB continue to empower the aerospace industry to reach new heights—literally.

Conclusion

Aerospace PCBs are the unseen backbone of satellite systems, ensuring power distribution, signal integrity, and overall system reliability. Working with a skilled aerospace PCB manufacturer like Insight PCB ensures that satellites can withstand extreme environments, operate flawlessly for years, and achieve mission success.

From Earth’s orbit to deep space exploration, reliable aerospace PCBs are essential for modern satellite technology—and Insight PCB is proud to deliver solutions that adapt, thrive, and perform in the harshest conditions imaginable.