Introduction to E-Beam Technology

In the bustling world of sterilization, the e-beam sterilizer is making waves as a game-changer. While traditional methods like heat and chemicals have long dominated the industry, e-beam technology offers a modern, efficient, and environmentally friendly alternative. This blog post will explore how e-beam sterilizers work, their benefits, and their applications across various industries. Whether you’re involved in healthcare, food production, or manufacturing, understanding this cutting-edge technology can help you stay ahead of the curve. Let’s shed some light on the science behind e-beam sterilization and its potential impact on your industry.

What is an E-Beam Sterilizer?

An e-beam sterilizer, or electron beam sterilizer, uses high-energy electrons to eliminate microorganisms from various products. Unlike traditional methods, which may rely on heat or chemicals, e-beam sterilization employs focused electron beams to penetrate products and destroy microbial DNA. This process is both quick and effective, making it ideal for industries where time and sterility are critical. The technology behind e-beam sterilizers allows for precise control, ensuring that products are thoroughly sterilized without compromising integrity. This cutting-edge technique is gaining popularity due to its efficiency and reduced environmental impact.

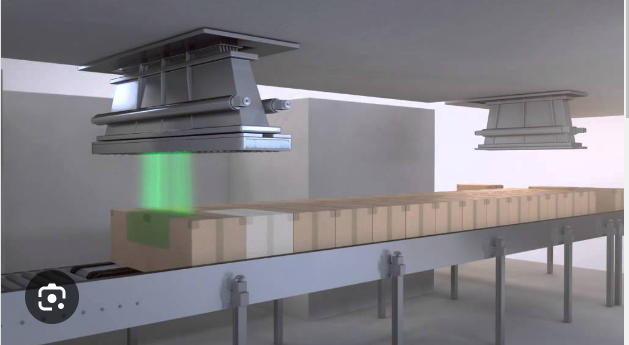

How Does E-Beam Sterilization Work?

E-beam sterilizer operates by accelerating electrons through a vacuum and directing them onto the surface of a product. These electrons penetrate biological cells, damaging their DNA and rendering them inactive. This non-thermal process is incredibly fast, often taking just seconds to achieve full sterilization. Because it doesn’t rely on heat, e-beam sterilization is ideal for materials sensitive to high temperatures. Furthermore, the ability to focus the electron beam ensures that even complex shapes and hard-to-reach areas receive equal treatment. This precision makes e-beam sterilization a versatile option for various industries.

Benefits of E-Beam Sterilization

The benefits of e-beam sterilization are numerous, making it an attractive option for modern businesses. Firstly, the process is incredibly fast, enabling high throughput and reducing downtime. This efficiency can lead to significant cost savings, especially in high-volume operations. Secondly, e-beam sterilization is environmentally friendly. Unlike chemical methods, it doesn’t rely on harsh substances that can harm the planet. Additionally, e-beam technology is highly precise, ensuring uniform sterilization without damaging the product. This level of control is particularly valuable for industries where product integrity is paramount.

Applications in Healthcare

In the healthcare sector, where sterility is non-negotiable, e-beam sterilization shines. Medical devices, surgical equipment, and even pharmaceuticals benefit from this technology. The speed and efficiency of e-beam sterilization reduce turnaround times, ensuring that critical supplies are available when needed. The non-thermal nature of the process also means that sensitive materials, such as polymers used in medical devices, remain intact. Furthermore, the precision of e-beam sterilizers guarantees that every nook and cranny of complex equipment is thoroughly treated, reducing the risk of contamination.

Food Industry Insights

The food industry faces unique challenges when it comes to sterilization. E-beam technology offers a viable solution for extending shelf life and ensuring safety without compromising quality. By eliminating pathogens and spoilage organisms, e-beam sterilization can enhance food safety and reduce waste. Unlike traditional methods that may alter taste or texture, e-beam treatment preserves the natural qualities of food products. This capacity makes it particularly appealing for fresh produce, packaged goods, and ready-to-eat meals. Additionally, the rapid processing time aligns well with the fast-paced nature of the food industry.

Advantages for Manufacturing

Manufacturers across various sectors are discovering the advantages of e-beam sterilization. This technology is particularly beneficial for electronics, textiles, and automotive components that require sterilization without heat. E-beam sterilizers provide a cost-effective way to ensure product safety and quality. The precision of the process reduces the risk of damage, while the speed enhances productivity. Furthermore, the absence of chemical residues aligns with increasing consumer demand for environmentally responsible practices. By adopting e-beam technology, manufacturers can meet stringent safety standards while maintaining a competitive edge.

Environmental Considerations

In today’s eco-conscious world, sustainability is a top priority. E-beam sterilization delivers on this front by reducing reliance on harmful chemicals and minimizing energy consumption. The process itself generates no harmful emissions, making it a cleaner alternative to traditional sterilization methods. Additionally, the reduced need for packaging materials, as products can be sterilized in bulk, contributes to lower waste levels. Businesses that prioritize environmental stewardship will find e-beam technology aligns with their green initiatives, helping them achieve sustainability goals while maintaining high standards of quality.

Safety and Compliance

Ensuring safety and compliance is crucial when implementing a new technology, and e-beam sterilization excels in this regard. Stringent regulations govern the use of sterilization methods, and e-beam technology meets or exceeds these standards across various industries. The process is inherently safe, with built-in mechanisms to prevent accidental exposure to radiation. Furthermore, e-beam sterilizers are designed with user safety in mind, incorporating features that safeguard operators during use. Compliance with international standards, such as ISO and FDA guidelines, ensures that products treated with e-beam sterilization meet the highest safety requirements.

Future Trends in Sterilization

As technology continues to evolve, so too does the field of sterilization. E-beam technology is poised to play a significant role in the future landscape, with ongoing research and development efforts focused on enhancing its capabilities. Innovations such as increased penetration depth and energy efficiency are on the horizon, promising even greater applicability across diverse sectors. Furthermore, the integration of automation and digital monitoring systems is set to streamline processes and improve accuracy. Businesses that invest in e-beam technology today will be well-positioned to leverage these advancements for future success.

Implementing E-Beam Technology

For businesses considering the adoption of e-beam sterilization, careful planning and execution are key. The first step is to conduct a thorough assessment of current sterilization needs and processes. This evaluation will help determine the feasibility and potential benefits of transitioning to e-beam technology. Collaborating with experienced providers is essential to ensure successful implementation. These experts can offer guidance on equipment selection, facility setup, and employee training. By taking a strategic approach, businesses can seamlessly integrate e-beam technology into their operations, reaping the rewards of enhanced efficiency and quality.

Conclusion

E-beam sterilization offers a glimpse into the future of sterilization, where speed, precision, and sustainability converge. Across industries, from healthcare to manufacturing, this innovative technology is redefining standards and unlocking new possibilities. By understanding the mechanics and benefits of e-beam sterilization, businesses can make informed decisions about its potential applications. For those ready to explore this cutting-edge solution, the time to act is now. Together, let’s illuminate the path to a safer, more efficient world through the power of e-beam technology.