Automation systems product assembly is revolutionising the way industries operate, offering a seamless blend of speed, accuracy, and cost-efficiency. As manufacturers face increasing demands for precision and output, automated technologies are becoming essential to maintain competitiveness. Expert Technologies Group provides state-of-the-art solutions in this field, helping companies optimise their production lines and meet market expectations.

What Are Automation Systems Product Assembly?

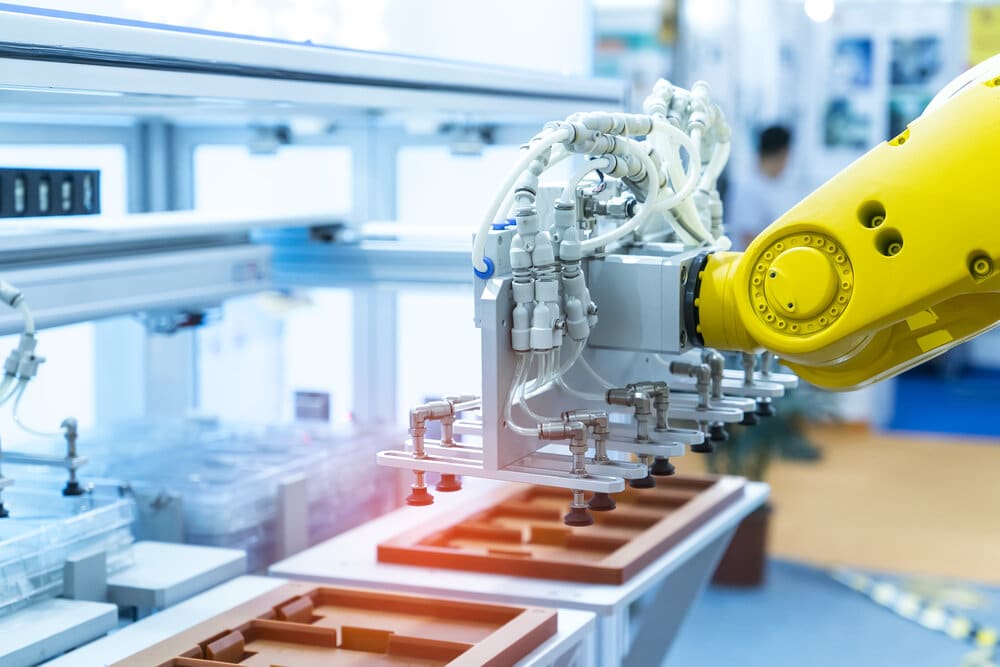

Automation systems product assembly refers to the use of integrated machines, robotics, and software to automate the process of assembling products. These systems perform repetitive tasks with precision, minimising the need for manual labour and reducing the potential for human error. The result is a faster, more efficient manufacturing process that ensures consistent quality.

Key Role of Automated Assembly Machines

Automated assembly machines play a vital role in automation systems product assembly. These machines are designed to handle complex tasks with precision, delivering numerous benefits to manufacturers:

- Higher Production Speeds: Automated systems operate faster than human workers, allowing businesses to meet production targets quickly and efficiently.

- Cost-Effectiveness: Automation reduces the reliance on manual labour, minimises waste, and improves productivity, generating long-term savings.

- Precision and Reliability: Automated machines ensure that each product is assembled to exact specifications, reducing defects and quality issues.

- Improved Safety: By automating dangerous or repetitive tasks, manufacturers create a safer working environment for their employees.

Components of Industrial Automation Systems Product Assembly

Industrial automation systems product assembly consist of multiple technologies working together to optimise the production process:

- Robotic Systems: These versatile machines can perform various tasks, from assembling components to packaging finished products. Their flexibility makes them suitable for a wide range of industries.

- Conveyor Systems: Automated conveyors ensure a smooth flow of materials and products between workstations, minimising downtime and bottlenecks.

- Control Software: Integrated software solutions monitor the entire assembly process in real-time, providing valuable insights for performance optimisation.

Benefits of Automation Systems Product Assembly

The adoption of automation systems product assembly delivers several key benefits:

- Increased Efficiency: Automated systems ensure continuous production with minimal interruptions, increasing overall output.

- Consistent Quality: Automation eliminates variability in the assembly process, ensuring uniform quality across all products.

- Scalability and Flexibility: Automated systems can be easily reconfigured to accommodate new products or changing production volumes.

- Data-Driven Improvements: With real-time data collection, manufacturers can identify inefficiencies and make informed decisions to optimise operations.

Choosing the Right Automation System

When selecting automation systems product assembly, businesses should consider:

- Production Needs: The system should align with the complexity and volume of the products being assembled.

- Budget and ROI: While automation involves upfront costs, long-term savings and productivity gains make it a worthwhile investment.

- Future Growth: A scalable system ensures that manufacturers can adapt to future demands without major disruptions.

Expert Technologies Group: Leaders in Automation

Expert Technologies Group provides tailored automation solutions that address the unique needs of each client. Their expertise in automated assembly machines and industrial automation systems product assembly ensures that businesses can achieve maximum efficiency and reliability. With a focus on continuous innovation, Expert Technologies Group supports companies at every stage, from system design to ongoing maintenance.

Conclusion

Automation systems product assembly is transforming the manufacturing landscape, helping businesses achieve faster production cycles, enhanced product quality, and reduced costs. Companies that embrace automation will be well-positioned to meet market demands and drive sustainable growth.

Partnering with Expert Technologies Group gives you access to industry-leading automation solutions. Whether you need automated assembly machines or a fully integrated system, our team is here to support your journey towards operational excellence. Contact us today to learn more about how we can optimise your production processes.