Industrial wiring got harder as plants added robots, sensors, and data links. Old point-to-point runs eat space and time, and every manual screw joint adds risk. Tool-free, modular connectors and terminal blocks fix that. In 2025, smart factories, modular skids, and stricter safety rules push everyone toward faster installs, cleaner panels, and easier audits. The result is leaner wiring that supports your uptime targets.

By evolving wiring systems for Industry 4.0 requirements

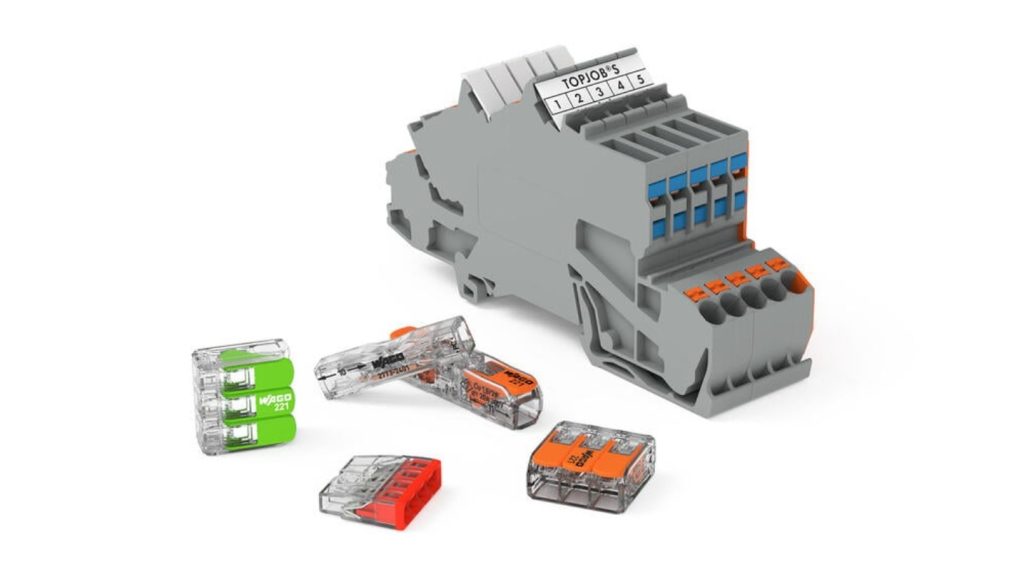

Right after you move past the intro, it helps to call out the role of Electric Wire Connectors in the middle of the sentence, because modern panels use them everywhere, delivering tool free terminations that cut installation time, reduce rework, improve current paths, and lower heat, and they also make inspections faster so your team spends less time with covers open and more time running production with safe, consistent joints. Push-in and Push-X style terminations let technicians seat rigid or ferruled conductors without tools, which speeds builds and changeovers. Studies and vendor data report up to 50 percent less wiring time versus screw types, a big deal when cabinets scale with Industry 4.0 nodes.

In lighting-heavy production areas, Lighting Connectors appear mid-run in tray and fixtures, giving quick disconnects for luminaires and controls, then helping maintenance swap, test, and reconfigure without pulling whole circuits, which trims downtime and keeps your energy projects on track while protecting consistent contact resistance in high duty cycles. Smart factory growth in 2025 only amplifies these wins.

By making installations faster and safer

Modular, plug-and-play blocks shorten cabinet builds, support kitting, and cut onsite labor. Tool-free springs control contact force, so joints stay stable during vibration. Better current paths and lower insertion forces also improve heat behavior, which protects nearby PLC IO and power supplies. Predictive programs can pair connectors and sensors, logging cycles and flagging trends for planned service, not surprise stops.

Where safety rules apply, designers lean on recognized standards. IEC 61984 defines connector safety tests, clearances, and creepage for industrial environments. For terminal blocks, UL 1059 2024 Edition 6 is the reference many auditors expect, with a transition now underway toward 2026 effective dates. Using listed components simplifies your compliance file.

By organizing panels with high density terminal block connectors

Terminal block connectors bring order to dense control panels. Marking channels, jumpers, and test points keep signals traceable, which shrinks troubleshooting time. High-density blocks lift circuits per rail, so you reclaim cabinet depth and width. That space reduction adds airflow and helps you meet thermal budgets without upsizing enclosures. Their clear labeling reduces cross-wiring errors, and UL 1059 recognition eases field wiring acceptance.

You also gain cleaner power distribution. Feed-through, ground, and multi-conductor blocks let you branch loads neatly across drives, IO, and lighting, and they pair well with digital monitoring modules that record load status for maintenance dashboards. Market data shows steady terminal block growth through 2030, aligned with automation investments.

By adding smart, sustainable, and smaller designs

Connectors are getting smarter. Some families integrate status pins or companion modules that log mating cycles and temperature, feeding predictive diagnostics so you can service before failure. Research shows data driven maintenance boosts reliability and cuts unplanned downtime, which is exactly what your OEE targets need.

Materials are improving too. Vendors now use recycled or lower-resin housings and optimized metals to reduce impact while keeping performance. Recent 2025 collaborations in automotive connectors demonstrate recycled polyamides at scale, and major connector makers report halogen-free, recycled housings with measurable resin reductions. That sustainability push aligns with your ESG goals without sacrificing ratings.

Finally, miniaturization matters. Slim blocks and compact circular or rectangular interfaces free rail space, enabling narrower cabinets that still meet current and ingress specs. New push-pull and push-in product specs for industrial power keep installs quick while holding 16 A class ratings per pole where needed.

So, they lift performance, reliability, and efficiency across smart factories

Put simply, modern connectors turn wiring into a repeatable, auditable process. You get faster builds, safer joints, cooler panels, and quicker swaps during changeovers. Layouts are maintained tidily and high-density with terminal block connectors, and intelligent and sustainable designs will discontinue living and help you tell your ESG story. In the year 2025, that smart backbone and that intelligent wiring can serve your smart factory expansion, energy grids to control cabinets, and assist you in reaching uptime and energy objectives with less surprises.