Conveyor belts are the unsung heroes of modern industry, tirelessly transporting goods and materials across factories, warehouses, and mining sites. Their continuous operation, however, makes them susceptible to damage over time. When a conveyor belt breaks down, it can halt production, disrupt workflows, and lead to significant financial losses. This is where Oliver Rubber steps in, offering expert Conveyor Belt Repair services that restore functionality and extend the life of these critical systems. In this blog, we’ll dive into why professional repair services matter and how Oliver Rubber excels in delivering reliable solutions.

The Necessity of Expert Conveyor Belt Repair

Conveyor belts face a variety of challenges daily—heavy loads, abrasive materials, and constant motion all take a toll. Common issues include tears, worn surfaces, misaligned belts, and weakened splices. While some businesses might consider patching up minor damage themselves, such makeshift repairs often fail under pressure, leading to bigger problems down the line. Professional Conveyor Belt Repair ensures that damages are addressed thoroughly, preventing unexpected downtime and maintaining workplace safety.

Oliver Rubber brings a wealth of experience to the table, specializing in repairs that go beyond surface-level fixes. Their team understands the intricacies of conveyor systems and uses proven methods to deliver lasting results. By choosing their services, businesses can avoid the pitfalls of temporary solutions and keep operations running smoothly.

What Sets Oliver Rubber Apart

Oliver Rubber has earned its place as a trusted name in Conveyor Belt Repair by combining expertise with innovation. Serving industries like manufacturing, agriculture, and logistics, they offer tailored solutions that meet the unique needs of each client. Their approach starts with a detailed assessment of the belt’s condition, followed by a repair plan designed to maximize durability and performance.

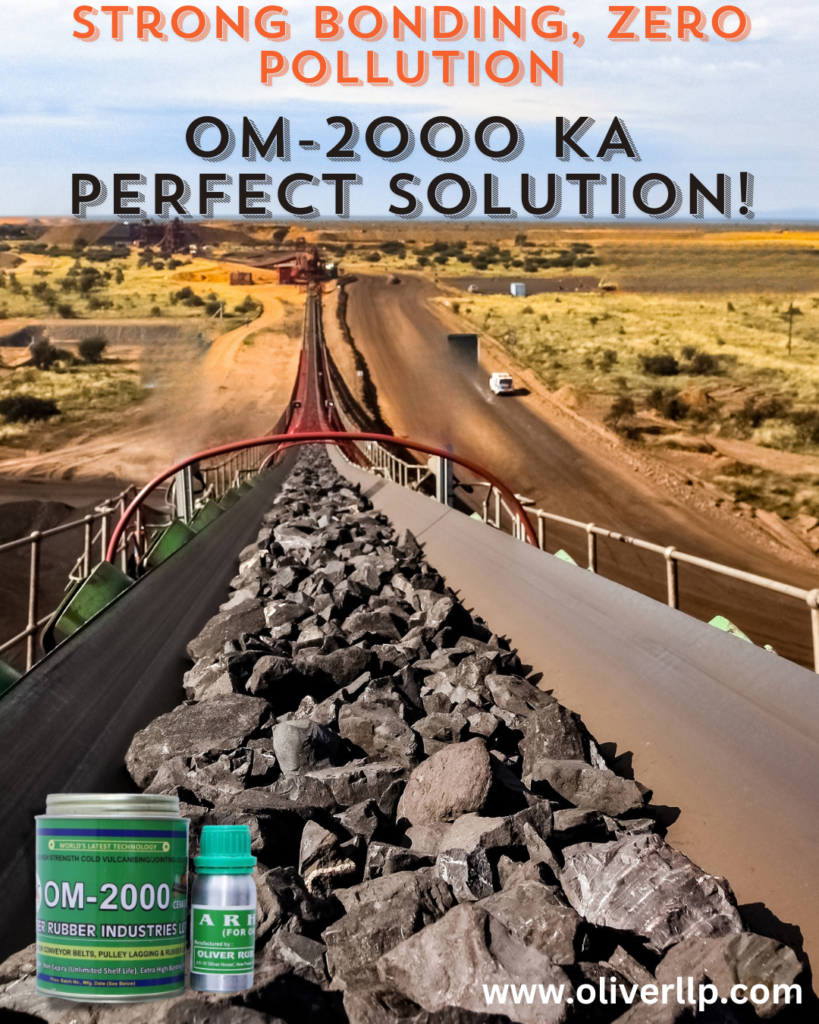

Their use of advanced techniques, such as hot vulcanization and cold bonding, ensures that repaired belts can withstand demanding conditions. Additionally, Oliver Rubber employs high-quality materials that match or exceed the original belt specifications. This commitment to excellence minimizes the likelihood of recurring issues, making them a go-to choice for businesses seeking dependable repairs.

Addressing Common Conveyor Belt Issues

Conveyor belts encounter a range of problems, each requiring a specific fix. Here’s how Oliver Rubber tackles some of the most frequent challenges:

- Rips and Tears: Sharp edges or overloading can tear belts apart. Oliver Rubber uses precision patching and bonding techniques to restore structural integrity.

- Tracking Issues: Misaligned belts wear unevenly and strain motors. Their technicians realign systems and adjust components for smooth operation.

- Surface Damage: Abrasion erodes belt surfaces over time. Protective coatings and durable patches from Oliver Rubber combat this wear.

- Splice Weakness: Poorly executed splices can fail under tension. Their expertly applied splices ensure strength and reliability.

These repairs demand skill and specialized tools—resources that Oliver Rubber brings to every job.

The Advantages of Choosing Oliver Rubber

When you opt for Oliver Rubber’s Conveyor Belt Repair services, you’re investing in efficiency and peace of mind. Their quick turnaround times minimize downtime, helping businesses stay on schedule. Repairs are also cost-effective, extending the belt’s lifespan and delaying the need for costly replacements. Safety is another priority, as their work adheres to industry standards, protecting both equipment and personnel.

Oliver Rubber also champions sustainability. By repairing belts rather than replacing them, they reduce waste and support eco-friendly practices—a win for both businesses and the environment.

The Power of Preventive Maintenance

Repairing a damaged belt is only part of the equation. Oliver Rubber emphasizes preventive maintenance to stop issues before they start. Regular inspections can identify early signs of wear, such as small cracks or loose fittings, allowing for timely interventions. Their customized maintenance plans keep conveyor systems in top shape, reducing the frequency of repairs and boosting productivity.

Why DIY Repairs Don’t Cut It

DIY Conveyor Belt Repair might seem like a budget-friendly option, but it often leads to more harm than good. Without the right expertise or materials, homemade fixes can weaken the belt or cause improper adhesion, resulting in failures under stress. Oliver Rubber eliminates these risks with professional-grade repairs backed by years of industry knowledge.

Partner with Oliver Rubber Today

A malfunctioning conveyor belt can disrupt your entire operation, but with Oliver Rubber’s Conveyor Belt Repair services, you’re in capable hands. Their dedication to quality, rapid response, and customer satisfaction ensures that your conveyor systems remain reliable and efficient. Whether you need an urgent repair or a long-term maintenance strategy, Oliver Rubber delivers results you can trust.

In summary, professional Conveyor Belt Repair is about more than just fixing damage—it’s about safeguarding your business’s productivity and profitability. Oliver Rubber’s expertise, innovative methods, and client-focused approach make them a leader in the field. Don’t let conveyor issues derail your operations; reach out to Oliver Rubber and experience the difference of top-tier service.