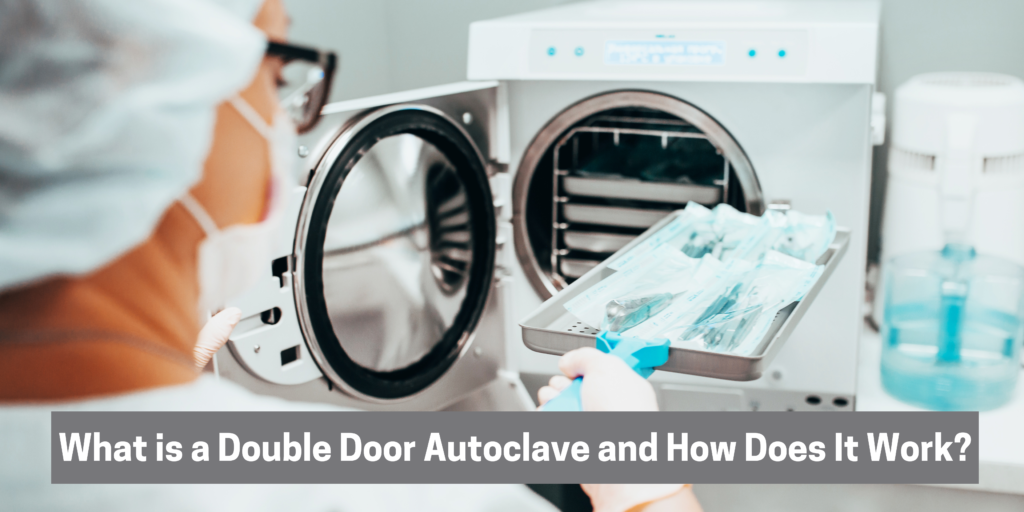

Autoclaves are essential pieces of sterilizing equipment, particularly in industries like research labs, pharmaceuticals, and healthcare. Among the different types of autoclaves, the double door autoclave is notable for its innovative design and efficiency. This specialized autoclave guarantees a high level of sterilization, adhering to the most stringent hygiene and safety standards.

In this blog, we’ll explore what a double door autoclave is, how it functions, and why Esporti Impex is recognized for providing top-notch autoclaves.

What is a Double Door Autoclave?

A double door autoclave, often referred to as a pass-through autoclave, is a sterilization device featuring two doors located on opposite sides. This distinctive design facilitates a unidirectional workflow, which is essential in settings where preventing cross-contamination is vital, such as hospitals, pharmaceutical manufacturing facilities, and cleanrooms.

Key Features of a Double Door Autoclave

Two Doors: One door is designated for loading unsterilized materials, while the other is for unloading sterilized items.

Unidirectional Workflow: This design helps maintain a clear separation between sterile and non-sterile areas.

Durable Construction: Typically constructed from stainless steel, ensuring durability and resistance to corrosion.

Customizable Sizes: Available in various capacities to meet diverse industrial and medical requirements.

How Does a Double Door Autoclave Work?

The double door autoclave functions on the same principles as standard autoclaves, utilizing high-pressure saturated steam to eliminate microorganisms, spores, and pathogens. The items to be sterilized are placed into the chamber, and both doors are securely sealed to maintain steam pressure. Once the cycle commences, the autoclave increases the temperature and pressure within to effectively eradicate harmful microorganisms.

The double doors create an airtight seal, which prevents steam from escaping and helps maintain the necessary pressure levels for effective sterilization. This careful process guarantees that medical instruments, laboratory tools, and other items are thoroughly sterilized and safe for use, making the Double Door Autoclave an essential device for upholding hygiene and safety standards. Additionally, its dual-door design enhances both efficiency and safety during the sterilization process.

Step-by-Step Process

Loading Unsterilized Items

You place items that need sterilization into the autoclave from the non-sterile side. You securely seal the door on this side to stop any steam from leaking out.

Pre-Sterilization Phase

The vacuum system or steam displaces the air from the autoclave chamber or removes it.

This step is crucial for ensuring that steam can penetrate the items evenly.

Sterilization Phase

Technicians then introduce high-pressure steam into the chamber. They typically set the temperature between 121°C and 134°C and maintain the pressure at around 15-30 psi for a specific time, depending on the materials they are sterilizing.

Post-Sterilization Phase

After sterilization, the system depressurizes the chamber and releases the steam. The process then uses a vacuum dryer to dry the items, ensuring no moisture remains.

Unloading Sterilized Items

After the sterilization cycle finishes, staff unlock the door on the sterile side. They then remove the sterilized items in a sterile environment to keep them uncontaminated.

Applications of Double Door Autoclaves

Double door autoclaves are mainly utilized in settings that demand the highest standards of sterilization and hygiene.

- Healthcare Facilities: For sterilizing surgical instruments, medical devices, and linens.

- Pharmaceutical Industry: To ensure the sterile production of medicines and vaccines.

- Research Laboratories: For sterilizing lab equipment, glassware, and biological waste.

- Food and Beverage Industry: To sterilize containers and packaging materials, maintaining hygiene standards.

Advantages of Using a Double Door Autoclave

Better Infection Control

The unidirectional workflow prevents contamination by making sure that sterilized products never come into contact with unsterilized materials.

Improved Productivity

Double door autoclaves facilitate simultaneous loading and unloading, thus streamlining operations in highly demanding environments.

International Sterilization Standards

The manufacturers designed these autoclaves to meet international sterilization standards, making them suitable for critical applications.

Customization

Double-door autoclaves are available in a wide range of sizes and configurations to suit individual needs in various industries.

Durability and Longevity

Made from tough steel, such as stainless, it is pretty durable and resists wear and tear.

Why Esporti Impex for Double Door Autoclaves?

Esporti Impex offers a comprehensive sterilization equipment range, including state-of-the-art double-door autoclaves. In a nutshell, this brand stands for quality, reliability, and innovation that the industry has come to rely on in business operations.

Key Features of Esporti Impex Double Door Autoclaves

Advanced Technology: Utilizes the most advanced sterilization technologies for optimal efficiency and safety.

Flexible Solutions: Provides various autoclave products in all sizes and configurations to meet any customer need.

Energy Efficiency: The product is designed to achieve optimal energy usage without compromising performance.

User-Friendly Design: Ideally, controls and monitoring systems allow for ease of operation.

After-Sales Support: The company provides comprehensive maintenance and support services to ensure seamless performance.

Industries Served by Esporti Impex

- Hospitals and healthcare centers

- Pharmaceutical and biotech companies

- Research and development laboratories

- Food and beverage production units

Maintenance Tips for Double Door Autoclaves

To ensure your double door autoclave operates efficiently and has a long service life, regular maintenance is essential.

- Regular Cleaning: Keep the chamber clean to prevent residue buildup.

- Inspection of Seals: Check door gaskets and seals for wear and replace them if necessary.

- Routine Calibration: Ensure temperature and pressure sensors are calibrated regularly.

- Use Quality Water: Avoid hard water to prevent scaling in the steam generation system.

- Follow Manufacturer Guidelines: Always adhere to the maintenance schedule provided by the manufacturer.

Conclusion

A double door autoclave is a sophisticated sterilization solution designed to meet the stringent hygiene and safety requirements of industries like healthcare, pharmaceuticals, and research. Its unidirectional workflow and advanced features make it an invaluable tool for maintaining sterile environments.

When it comes to investing in a high-quality double door autoclave, Esporti Impex stands out as a trusted name. With its commitment to innovation and quality, Esporti Impex provides solutions that cater to the diverse needs of its clients, ensuring optimal performance and reliability.

If you’re looking for a double door autoclave that combines efficiency, durability, and state-of-the-art technology, explore the offerings from Esporti Impex and elevate your sterilization standards today!